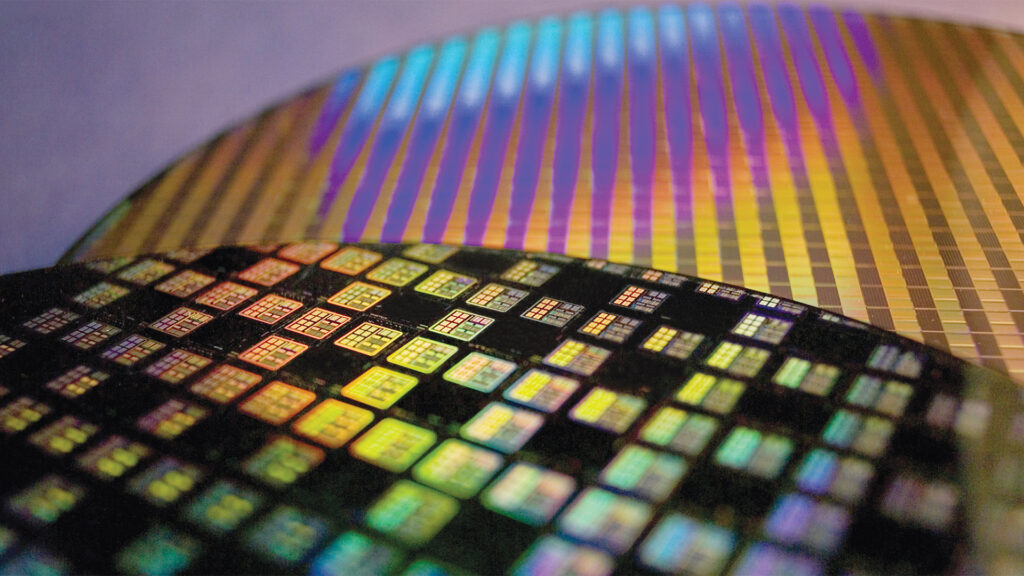

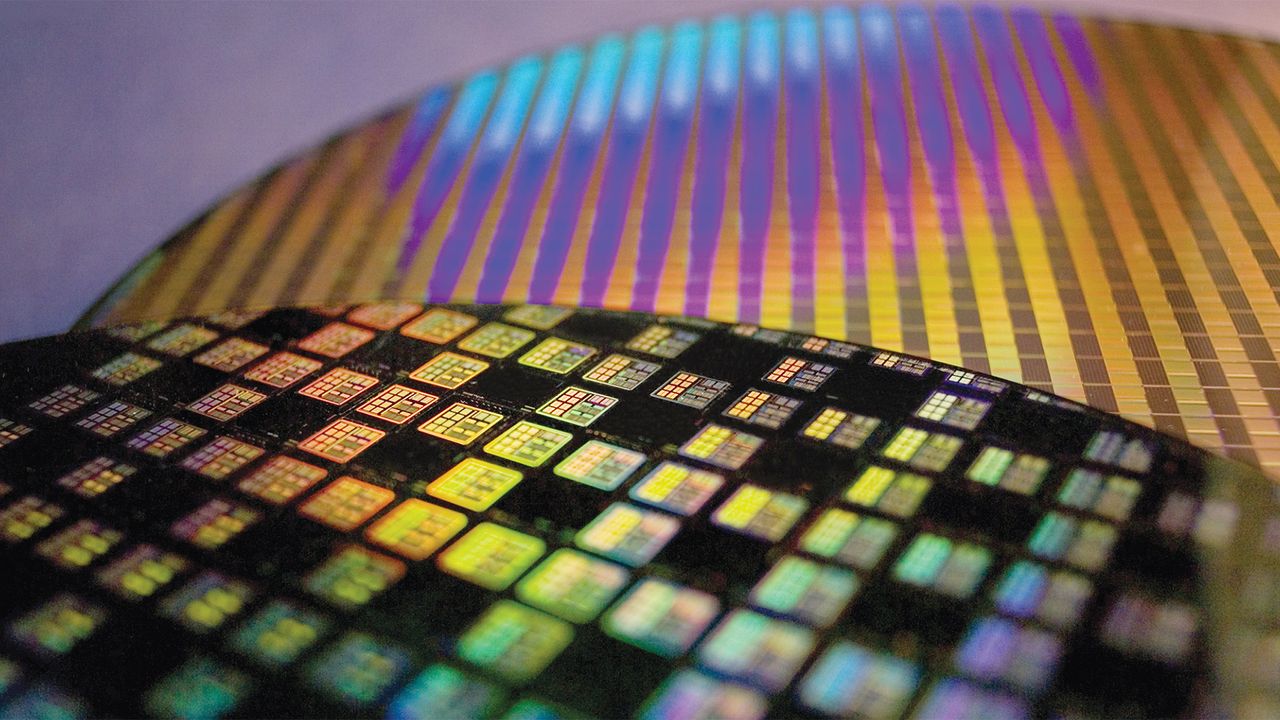

Misplaced yield from stochastics is costing chipmakers billions at superior course of nodesCurrent course of management strategies will not be sufficient to unravel high-volume stochastics failuresNew whitepaper outlines design and measurement options to shut stochastics gapA new whitepaper has claimed the semiconductor {industry} is dropping billions of {dollars} as a consequence of one thing few outdoors the sector have heard of: stochastic variability.This type of random patterning variation is now thought-about the most important hurdle to attaining excessive yields on the most superior course of nodes.The paper was contributed by Austin, Texas-based Fractilia, whose CTO, Chris Mack, famous, “Stochastic variability is contributing to multibillion-dollar delays in introducing superior course of expertise into excessive quantity manufacturing.”

You might like

Affecting yield, efficiency and reliabilityMack additional defined present course of management methods haven’t been capable of tackle these random results.“Closing the stochastics hole requires utterly completely different methodologies that gadget makers must validate and undertake,” Mack stated.Fractilia defines this “stochastics hole” because the distinction between what may be patterned in analysis and what may be reliably mass-produced at acceptable yields.On the coronary heart of this hole is a randomness rooted within the physics of supplies, molecules, and light-weight sources utilized in chip manufacturing.Signal as much as the TechRadar Professional publication to get all the highest information, opinion, options and steerage your small business must succeed!Though these results have been as soon as negligible, they now devour a rising share of the manufacturing error price range.“Now we have seen our prospects make dense options as small as 12 nanometers in analysis and improvement,” Mack stated. “However after they attempt to transfer it into manufacturing, stochastic failures are affecting their means to realize acceptable yield, efficiency and reliability.”The issue has grown alongside the rise of EUV and high-NA EUV lithography. These advances have allowed chipmakers to aim even smaller options, but in addition made them extra susceptible to stochastic defects.In contrast to typical variability, this sort can’t be eradicated with tighter controls, it must be managed with probability-based design and measurement methods.“The stochastics hole is an industry-wide downside,” Mack stated. “This concern may be minimized and managed, nevertheless it all begins with correct stochastics measurement expertise.”The whitepaper, which you’ll be able to obtain right here, consists of an evaluation of the issue and proposes stochastics-aware design, supplies innovation, and up to date course of controls as the trail ahead.You may additionally like